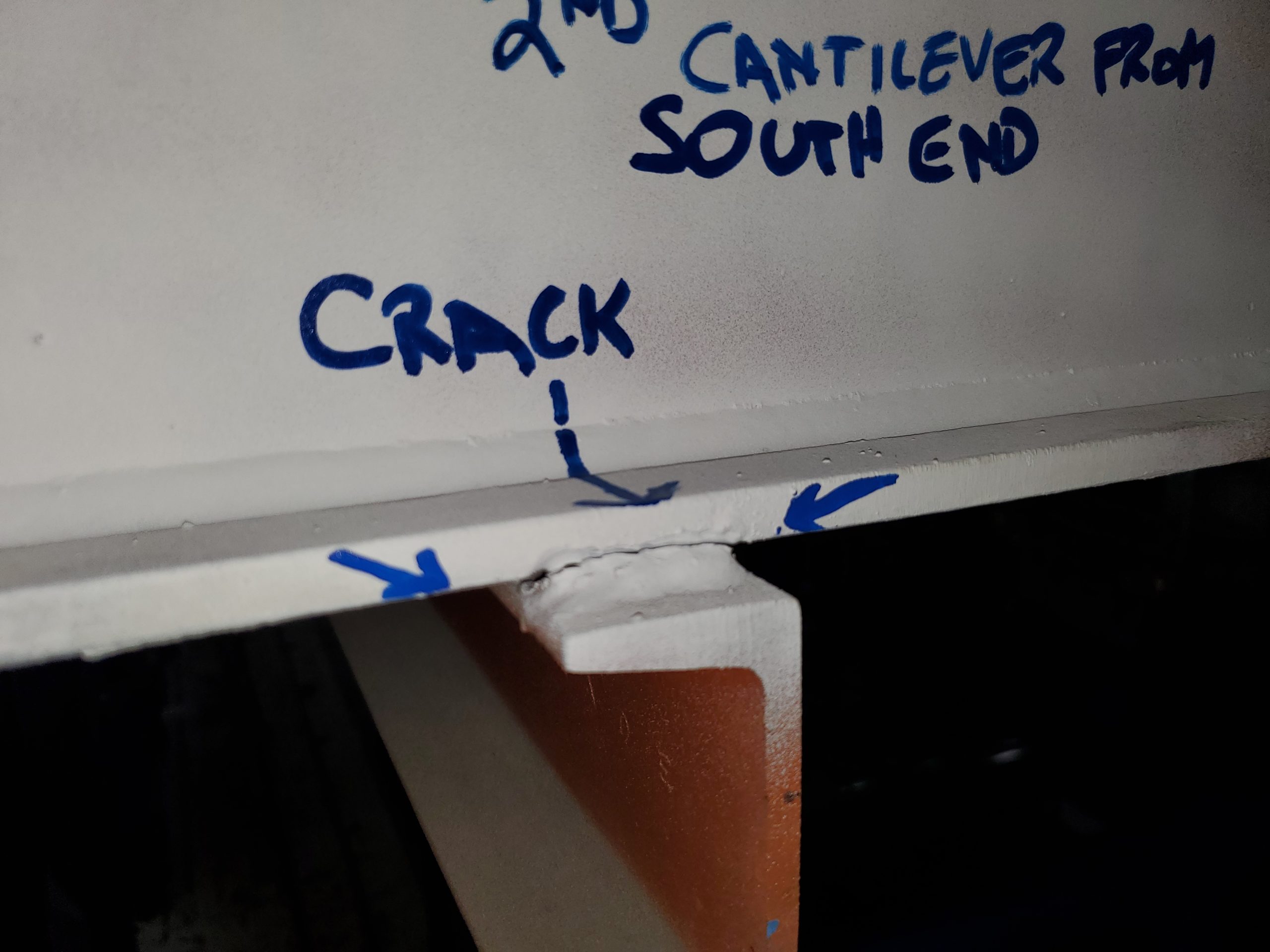

CGSB 48.9712 Non Destructive Testing

Magnetic Particle and Dye Penetrant NDT Methods used to indicate surface cracks and weld defects in new and existing structural steel and equipment. Over time, metal fatigue or residual stress can cause cracks in heavy machines or steel structures and components. Cracks in the weld area during the fabrication process can also lead to component failure. Non destructive testing by magnetic particle inspection on carbon steel components can map out defects prior to service or after repeated use.

Call us to request an appointment, Contact us for a quote or inspection.

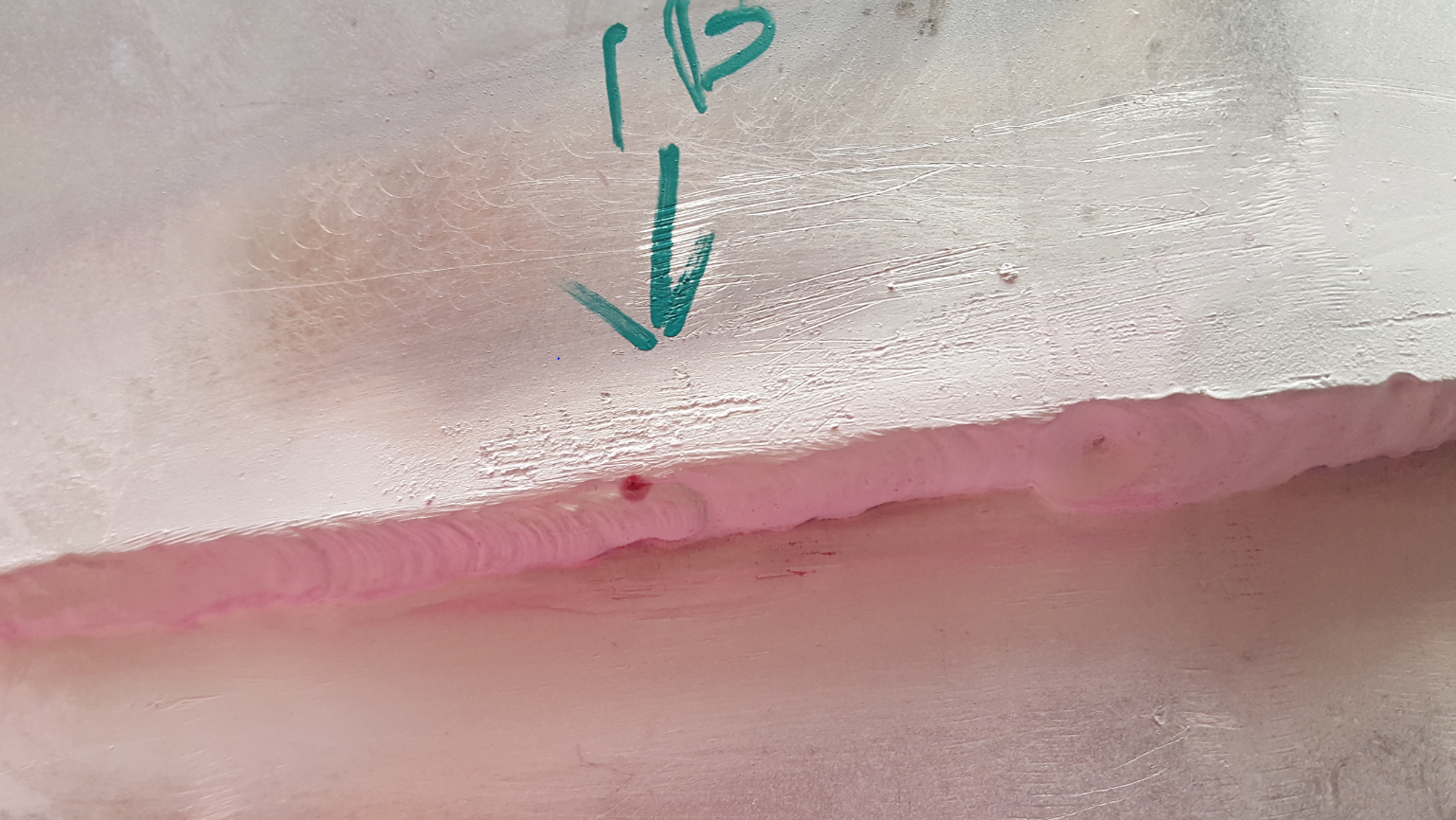

Liquid Penetrant Inspection

Stainless steel or aluminum components are often used in industry for their specific characteristics. As these alloys are not magnetic (excluding duplex steels) Liquid penetrant inspection is often required after fabrication to indicate cracks, porosity or cold roll among other weld defects that are not desirable. These defects can cause failure if not corrected.

Call us to request an appointment, Contact us for a quote or inspection.